Services:

Recycling

Repurposing Is Our Purpose.

At DTG, you’ll find an Earth-first mindset in everything we do. Whether it’s taking in an old carpet or a clunky chunk of concrete, we’re proud to recycle on a prolific level, pioneering a new path to real sustainability.

Recycling Service That Works For You

With multiple drop-off locations, next-level technology, and dedicated operations for handling unique materials, we make it easy to go green.

Asphalt & Concrete

DTG offers advanced asphalt & concrete recycling services turning asphalt and concrete into materials for roads, driveways, and other construction applications, reducing costs and landfill waste, with drop-off options and competitive pricing since 1999.

Cardboard

DTG has multiple cardboard recycling facilities throughout Washington. Click here to learn about drop-off times and locations.

Carpet

Need to recycle carpet? We have you covered. DTG has several facilities across Washington State to help you keep your carpet out of the landfill. Give us a call today to learn more!

Commingled

DTG accepts commingled materials at several of our facilities across Washington state. Give us a call to learn more!

Dirt

DTG Recycle has Dirt Recycling Centers all over Washington State. Give us a call if you need to rent a dumpster for your dirt or want to learn more about where we accept dirt for drop-off.

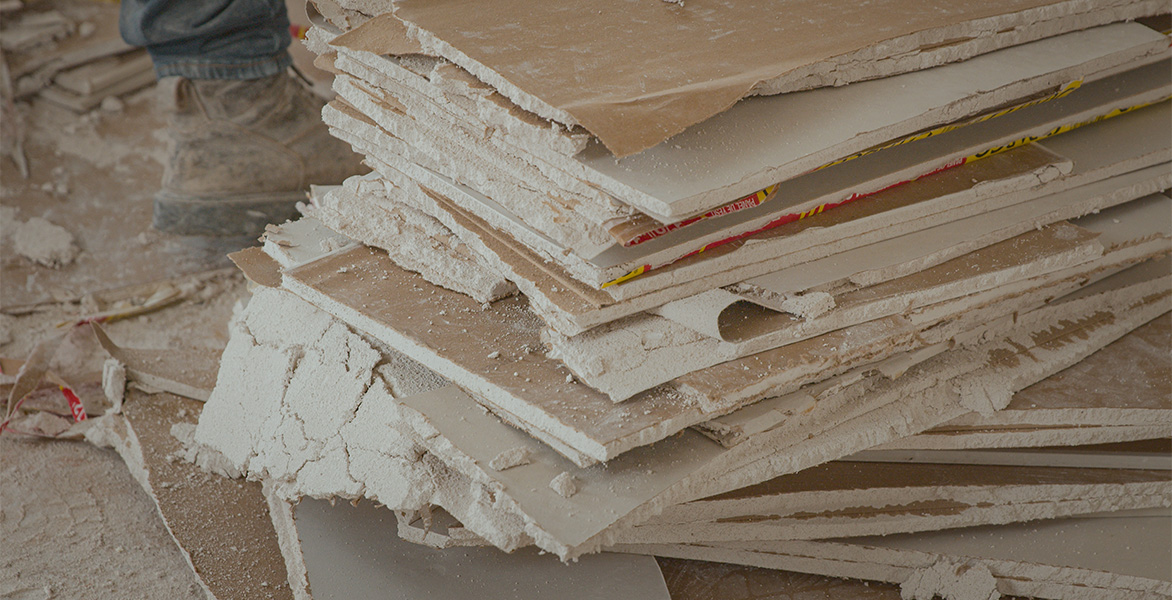

Drywall

Drywall recycling is a more economical and environmentally safe option than disposal. DTG provides the best recycling facilities; find a location near you.

Mattresses

Get rid of your old mattress at one of our mattress recycling facilities. Recycling is an easy and budget-friendly option with DTG.

Organics

DTG is your go-to brush, stump, and land-clearing material recycling center. Give us a call or visit our Snohomish, Bremerton or Kingston locations to drop off your organics!

Plastic

DTG uses advanced sorting methods in all our plastic recycling facilities. Safely get rid of plastic while saving time and money. Find a location near you.

Roofing

Get rid of extra or broken roof shingles. DTG offers roofing recycling facilities throughout the state of Washington. Find a drop-off location near you.

Styrofoam

Styrofoam recycling is an easy and low-cost option with DTG. Find one of our many recycling facilities near you!

Wood

Get fast and affordable wood recycling services from DTG. We have wood recycling centers all over Washington state. Find one near you!

Ready to drop off?

Specialty recycling

From cash for your scrap metal to expertly handling e-waste, DTG is HQ for all things recycling.

Metal Buy-Back

We recycle more metal than a Twisted Sister cover band, offering advanced sorting technologies at all our metal recycling centers across Washington.

E-waste

Electronic waste is booming, but we’re fighting back. Bring us your old phones, laptops, & more. We’ll responsibly recycle them, conserving resources and preventing pollution.

Certified Destruction

Trust DTG for the certified destruction of your private data and all products that are faulty,

counterfeit, expired, recalled, below standards, or otherwise unusable.

Request a quote

We got you.

Please fill out this form to request a quote. You will receive a call from us within 1 business day.

the dtg standard

Since our humble beginnings in 1999, with just a single truck and a vision, DTG has emerged as the premier recycling and site services partner in the Pacific Northwest. Whether you’re a general contractor, manufacturer, or construction project manager, you can expect world-class customer support and personalized assistance every step of the way. With an unwavering commitment to a cleaner planet, we remain dedicated to going above and beyond your needs, delivering rock-solid reliability, flexible scheduling, fair pricing, and a variety of service offerings. That’s the DTG standard.

Dedicated Local Support

Unmatched Reliability

Flexible Scheduling

Full-Service Capability

Explore More DTG Services

Landscape Materials & Organics

Our Organics division offers a broad range of top-quality landscape materials for contractors

and homeowners, with options for pickup or delivery, as well as professional bark blowing

services.

Recycling Dumpsters

Need a recycling dumpster rental for your clean-up or tear-down project? We’ve got you. Our roll-off dumpsters come in a wide variety of sizes, making them perfect for all commercial and construction recycling uses.